200kVA Epoxy Resin Pouring Transformer

PRODUCT INTRODUCTION PRODUCT OVERVIEW Epoxy resin pouring transformer is a solid insulation encapsulated winding power t

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 200kVA Epoxy Resin Pouring Transformer |

| Application | Power, Electronic, Instrument, Lighting, Rectifier, Audio |

| Phase | Three |

| Core | Core-type Transformer |

| Cooling Method | Dry-type Transformer |

| Winding Type | Two-winding Transformer |

| Certification | ISO9001-2000, ISO9001, CCC |

| Usage | Single-phase Transformer, Rectifier Transformer, Combined Transformer, Power Transformer, Distribution Transformer, Power Transmission and Transformation Systems |

| Frequency Characteristics | Power Frequency |

| Shape of Core | Ring |

| Brand | OEM |

| Rated Capacity | 200kVA |

| Rated Voltage-Primary | 10kv, 6kv |

| Rated Voltage-Secondary | 0.4kv and Other |

| Rated Frequency | 50Hz |

| Cooling | an/Af |

| Insulation Temperature Resistance Grade | F |

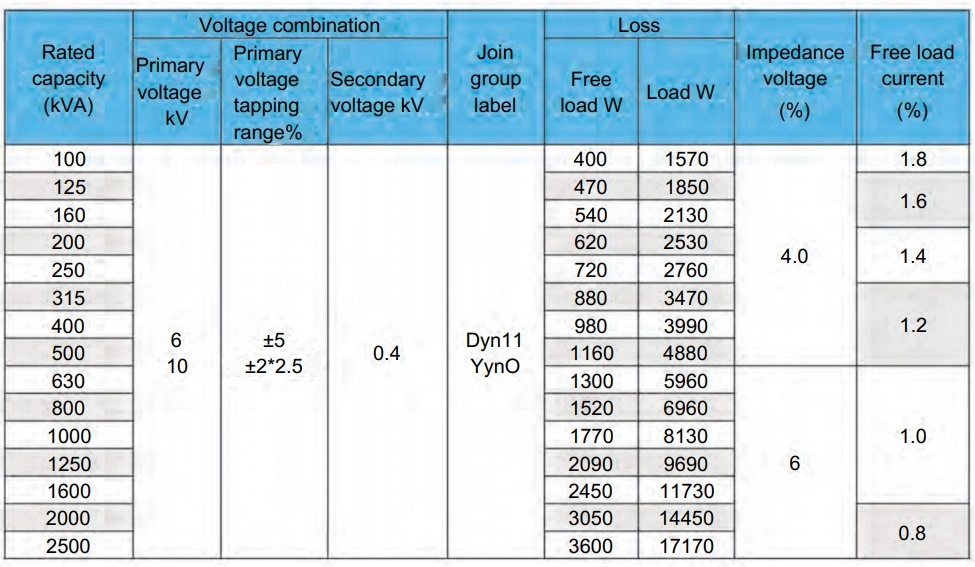

| Free Load | 620W |

| Load | 2530W |

| Free Load Current | 1.4% |

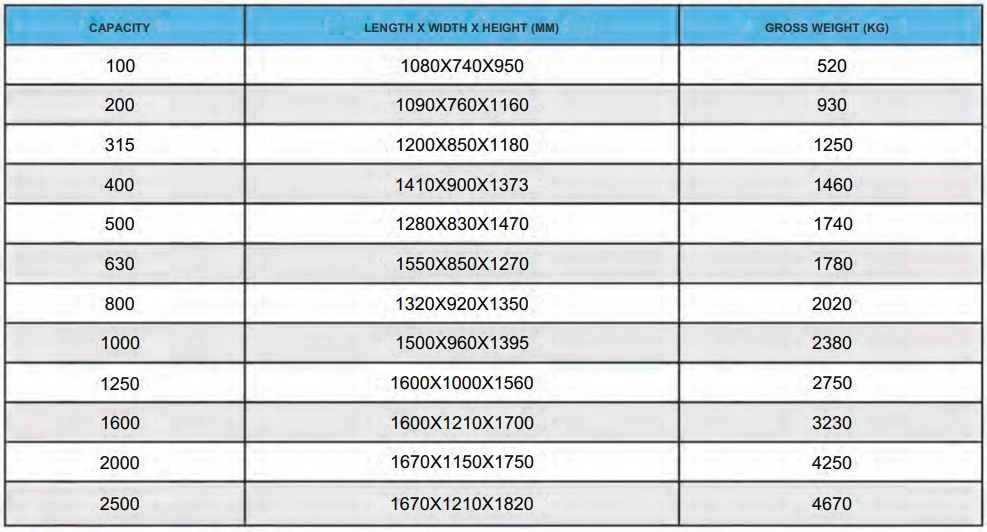

| Size (Lwd) | 1090X760X1160 mm |

| Gross Weight | 930 Kg |

| Transport Package | Wooden Case Packing, Container Shipping |

| Specification | Weight: 520-4670kg |

| Trademark | OEM |

| Origin | China |

| Production Capacity | About 4000 Set/Year |

Product Description

PRODUCT INTRODUCTION

PRODUCT OVERVIEW

Epoxy resin pouring transformer is a solid insulation encapsulated winding power transformer. Epoxy resin dry-type transformer uses epoxy resin as insulation material. High and low voltage winding is made of copper strip (foil), epoxy resin is poured and solidified in vacuum to form high strength FRP body. Insulation grade is F and H. Epoxy resin dry-type transformer has the characteristics of good electrical performance, strong lightning shock resistance, strong short-circuit resistance, small size and light weight etc.. The temperature display controller can be installed to display and control the operating temperature of the transformer winding to ensure the normal service life of the transformer.

PERFORMANCE CHARACTERISTICS

1. No oil, no pollution, flame retardant, self-extinguishing and fire prevention.2. Low loss, high efficiency and low noise. It can run long time under 125% rated load under the forced air-cooling condition and is equipped with intelligent temperature controller. The functions of fault alarm, over temperature alarm, over temperature trip and black gate. It is connected with computer through RS485 serial interface and achieves centralized monitoring and control.

3. Small local discharge (under 30 PC) and high reliability, can ensure long-term safe operation, life up to 30 years.4. Resistance to crack and temperature change, high mechanical strength, strong ability to resist sudden short-circuit.5. Good moisture-proof property, it can run normally under 100% humidity and can be put into operation without drying treatment after shutdown.6. There is no need for a separate transformer room, core maintenance or load-bearing beam saving civil land and occupation No oil, so it will not produce toxic gas to pollute the environment. No need of oil collecting pits or other ancillary buildings which reduces the cost of construction Easy installation, no debugging, almost no maintenance; No need to replace or check the oil, low operation and maintenance cost.TECHNICAL PARAMETER1. Rated capacity: 100-2500kVA2. Rated voltage: Primary voltage: 10kV, 6kV Secondary voltage: 0.4kV and other3. Rated frequency: 50Hz4. Phase number: Three-phase5. Cooling method: AN/AF6. Temperature resistance grade of insulation materials: Grade F7. Technical performance data and insulation level is shown in Table 1 and 2

Table 1 Performance parameters of dry-type transformer with rated voltage of 6 KV and 10 KV

Table 2 Insulation Level

PRODUCT SIZE

APPLICATION AREA

1. Power transmission and transformation systems, such as hotels, airports, high-rise buildings, commercial centers, residential districts and etc..

2. Harsh environment such as subways, smelters, ships, offshore drilling platforms, and etc..

COMPANY PROFILE

ABOUT US

Shanxi Huaxin Electric is located in Yangquan, the largest anthracite base in China. Founded in May 2003, the company's registered capital was RMB 114 million, with total assets of RMB 815 million and the existing staff of over 1100. At present, our company has six industrial parks, divided into Changling Industrial Park, Four Mining Industrial Park, Lock Spring Industrial Park, Taiyuan Industrial Park, Jinnan Remanufacturing Park, and Jindong Remanufacturing Park, covering a total area of over 650 acres.

Our company has more than 30 patents now, mainly engaged in the R&D and production of intelligent electric automation, intelligent transportation and lifting, intelligent warehousing, power system, ventilation fluid and other series of over 80 products.Our company has registered five R&D institutions in Beijing, Shenyang, Shanghai and Taiyuan, laying a solid foundation for technical upgrading and renewing generation for products. And it has been responsible for the production of the high-efficiency, energy-saving core technology products required by the national Eleventh Five-year plan, and the research and development of the high-efficiency permanent magnet motor and frequency conversion control, the key projects of national energy-saving for the Twelfth Five-year plan.

CERTIFICATIONS

AWARDS

1.High-tech Enterprise, Provincial Technology Center2.Two-phase Fusion Demonstration Enterprises3.China Quality and Integrity Enterprise4.Shanxi Top 100 Enterprises5.Shanxi Top 100 Manufacturing Enterprises6.Following Contract and Observing Credit Enterprise7.Shanxi Quality and Reputation AAA-Class Enterprise8.Small and Medium-sized Enterprises of Science and Technology9.Technology Center of Shanxi Small and Medium-sized Enterprises10.ISO9001 Quality Management System11.ISO14001 Environmental Management System12.ISO18001 Occupational Health and Safety Management System13.National Torch Program14.Golden Bridge Award of China Technical Market15.Measurement Guarantee Unit

ACHIEVEMENTS

1.The first production enterprise in rare earth flameproof permanent magnet motor and flameproof flat coil core transformer for mining.2.One of the country's three major mining transformation production bases, and the largest coal machine equipment manufacturing enterprise in Shanxi province.3.The permanent magnet direct drive motor and frequency conversion control produced by our company, have put into use in Zhengzhou Coal Industry Group, Shanxi Coal and Chemical Industry Group, Yangquan Coal Industry Group and other major coal industry groups.4.Distribution transformer products have been successfully shortlisted as qualified suppliers for National Power Grid and China Southern Power Grid.

ATTENTION

1. The payment term: We accept TT, 30% deposit and 70% balance against copy of BL.2. The delivery time: Usually it will take about 3 months.3. The standard of package: Usually use strong plywood case for protection.4. Warranty: In 12 months since BL date.

SERVICE

1. Reply within 24 hours.2. Perfect service commitment.3. Provide services during the pre-sales, in-sales and after-sales, all the way (Including quality warranty).4. Be free of charge in training and tutoring after sales.

CONTACT US

Foreign Trade Manager: Miss Yue Ding

Related Products

-

![Customized Toroidal Core Inductor Choke Coil]()

Customized Toroidal Core Inductor Choke Coil

-

![Power SMD Micro Speaker Coil 0.1uh 1uh 3.3uh 4.7uh 150uh 82uh 50uh 47uh 33uh 22uh Fixed Inductor]()

Power SMD Micro Speaker Coil 0.1uh 1uh 3.3uh 4.7uh 150uh 82uh 50uh 47uh 33uh 22uh Fixed Inductor

-

![7mh Ferrite Core Transformer Common Mode Variable Adjustable Power Inductor]()

7mh Ferrite Core Transformer Common Mode Variable Adjustable Power Inductor

-

![High Sensitivity 300 Degree Radial and Axial Glass Encapsulated Bead Thermistors 1K, 5K, 10K, 20K, 50K, 100K for Electronics, Temperature Measurements]()

High Sensitivity 300 Degree Radial and Axial Glass Encapsulated Bead Thermistors 1K, 5K, 10K, 20K, 50K, 100K for Electronics, Temperature Measurements